Why Chikin Packed Machine with Vacuum

Mar 06, 2025

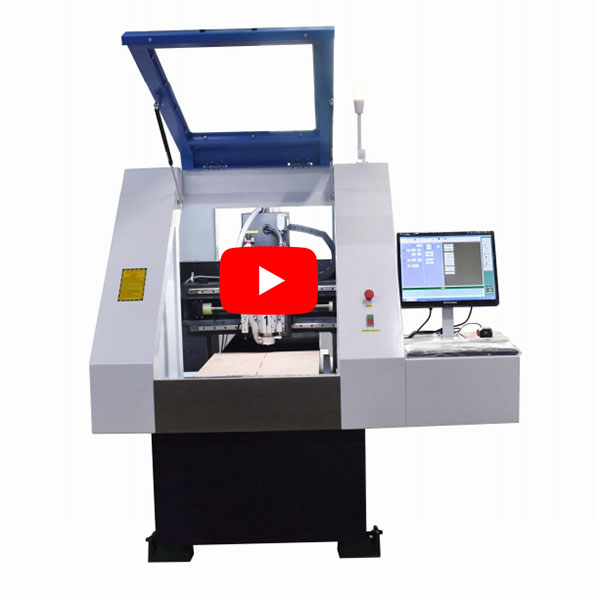

CNC PCB Drilling Machine generally does not require vacuum packaging, but Chikin all packed with Vacuum sytle for more better protect machine.

1. Transportation and Storage Conditions

- Humid Environment: If the equipment is stored for a long time in a high-humidity environment, vacuum packaging can help reduce the risk of moisture absorption and oxidation, especially for internal electronic components.

- Long-Distance Transportation: If the machine is being shipped over long distances, especially internationally, vacuum packaging can help protect it from temperature and humidity fluctuations.

2. Equipment Protection Needs

- Dust and Contamination Prevention: Although drilling machines typically have protective measures, vacuum packaging can provide extra protection against dust, oil, and other contaminants during storage or shipping.

- Rust and Oxidation Prevention: If certain metal components of the machine are sensitive to oxidation, vacuum packaging can slow down the oxidation process.

3. Cost and Practicality

- Vacuum packaging adds extra costs and complexity. It is more commonly used for small precision electronic devices. For larger, more robust equipment like PCB drilling machines, protective measures such as moisture-proof bags, desiccants, shock-absorbing foam, or wooden crates are more commonly used instead of full vacuum packaging.

Conclusion

In most cases, vacuum packaging is not necessary for a PCB drilling machine. However, if the storage or transportation conditions are harsh (e.g., high humidity, prolonged storage, or long-distance shipping), moisture-proof and shock-resistant packaging—or even vacuum packaging—can be considered to enhance protection.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points