Which factors affect the PCB Cost? And how to reduce it?

Jul 11, 2023

Which factors affect the PCB Cost? And how to reduce it?

The cost of a PCB (Printed Circuit Board) is influenced by several factors. Understanding these factors can help you identify areas where cost reduction is possible. Here are some key factors that determine PCB cost and strategies to reduce it:

- 1.PCB Size and Complexity: Larger PCBs and those with complex designs, multiple layers, or high component density generally require more materials, manufacturing time, and advanced processes, leading to higher costs. To reduce costs, optimize your PCB design by minimizing size, reducing the number of layers, and simplifying the layout without compromising functionality.

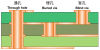

- 2.Number of Layers: PCBs can have single-sided, double-sided, or multi-layer constructions. As the number of layers increases, the cost of materials, manufacturing processes, and assembly also increases. If possible, consider using fewer layers by improving component placement and routing techniques.

- 3.Board Thickness: Thicker PCBs require more raw material, longer processing time, and specialized manufacturing techniques, leading to higher costs. Evaluate the mechanical and electrical requirements of your design and choose the minimum required thickness to reduce costs.

- 4.Material Selection: The choice of PCB substrate material affects cost. FR-4 is a common and cost-effective material, while specialty materials like high-frequency or high-temperature laminates can significantly increase costs. Select materials that meet your design requirements without unnecessary over-specification.

- 5.Copper Weight: The thickness of the copper layer on the PCB impacts cost. Higher copper weights (measured in ounces) require more copper foil, etching chemicals, and longer etching times. Analyze your design requirements and select an appropriate copper weight to balance cost and performance.

- 6.Surface Finish: Different surface finishes, such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), or OSP (Organic Solderability Preservatives), have varying costs. Choose a surface finish that meets your functional and cost requirements.

- 7.Quantity: PCB manufacturing costs are often inversely proportional to the quantity ordered. Higher volume orders typically offer economies of scale and reduced setup costs. Consider batch ordering or increasing your order quantity to reduce the cost per board.

- 8.Assembly and Testing: The complexity of PCB assembly, including the number of components, surface mount technology (SMT) vs. through-hole components, and testing requirements, can impact costs. Simplify the assembly process, optimize component selection, and test procedures to reduce costs without compromising quality.

- 9.Supplier Selection:Different PCB manufacturers offer varying pricing structures, capabilities, and quality levels. Obtain quotes from multiple suppliers, compare their offerings, and select a reliable supplier that provides a balance of cost, quality, and customer support.

- 10.Design for Manufacturability (DFM):Adopt DFM principles during the PCB design phase to minimize manufacturing issues and reduce costs associated with design revisions, rework, or scrap. Collaborate with your PCB manufacturer early in the design process to ensure manufacturability and cost-effectiveness.

By considering these factors and implementing design optimization techniques, material selection, and efficient manufacturing processes, you can help reduce PCB costs while maintaining the desired functionality and quality.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points