What Do You Need To Know Before You Entry PCB Industry

Mar 31, 2025

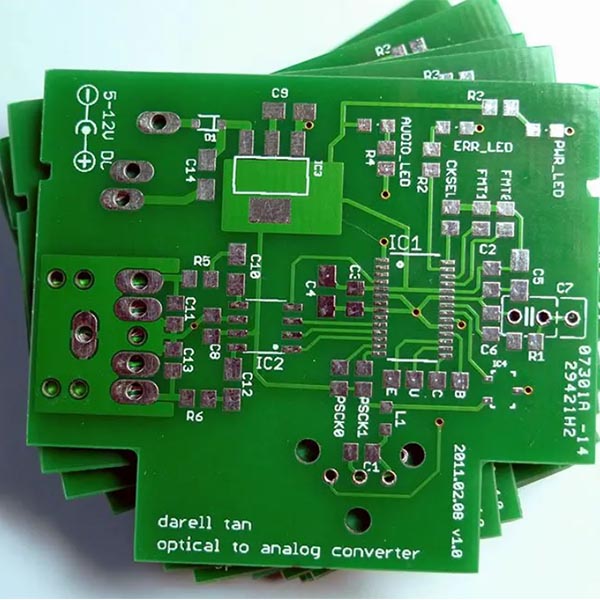

FR4 (Flame Retardant 4) is a common substrate used to manufacture printed circuit boards (PCBs). It is a glass fiber reinforced epoxy resin composite material with good mechanical strength, heat resistance, electrical insulation and flame retardancy.

Main features of FR4

Material composition:

Glass fiber cloth (provides mechanical strength)

Epoxy resin (provides insulation and heat resistance)

Flame retardant (makes it reach UL94-V0 flame retardant grade)

Performance characteristics:

High temperature resistance (usually can withstand 130-150°C, some high TG FR4 can reach 170-180°C)

High mechanical strength (bending resistance, impact resistance)

Good electrical insulation (suitable for electronic circuits)

Low moisture absorption (maintains stable performance in humid environments)

Flame retardant (UL94-V0 level, non-flammable)

Applications:

PCB (single-layer board, multi-layer board)

Electronic insulation material

Mechanical structural components

Because FR4 has both insulation, mechanical strength and heat resistance, it is widely used in PCB manufacturing and is one of the most common circuit board substrates.

What do you need to know to make a PCB drilling machine?Making a PCB drilling machine involves knowledge and skills in multiple fields, including mechanical design, electrical control, software programming, and PCB processing technology. The following are the main contents that need to be mastered:

1. Mechanical structure design

(1) Machine tool design

Gantry or cantilever structure design

Guide and screw selection (high-precision ball screw, linear guide)

Spindle system (high-speed spindle, usually 50,000~300,000 RPM)

Automatic tool change system (ATC) to improve efficiency

(2) Precision motion control

High-precision servo motor or stepper motor to ensure drilling accuracy

Motion control algorithm (linear interpolation, circular interpolation)

Error compensation technology (temperature compensation, mechanical error compensation)

2. Electrical and control systems

(1) CNC system

Motion control card (such as DSP, FPGA or PC-Based control)

G code analysis (PCB drilling program is usually in Excellon format)

Visual alignment system (improve alignment accuracy)

(2) Electrical part

High frequency variable frequency drive (drives the spindle motor)

Power management (ensures stable power supply)

Safety protection circuit (overcurrent, overload protection)

3. PCB processing technology

PCB materials (FR4, CEM-3, high frequency materials, etc.)

Drilling process:

Micro holes (less than 0.1mm) and ordinary holes (0.2~0.5mm)

Multilayer board drilling (positioning accuracy requirements between different layers)

Laser drilling vs mechanical drilling

Vacuum cleaning system (clean drilling dust and prevent pollution)

4. Computer vision and automation

CCD visual alignment system (identify positioning points and improve drilling accuracy)

Automatic loading and unloading (robot or vacuum suction cup)

AI detection (drilling error analysis)

5. Software and data processing

CAM software support (Genesis, CAM350, AutoCAM)

G code analysis (Excellon or Gerber file processing)

Motion control software (LabVIEW, C++, Python)

6. Other key technologies

Environmental control (constant temperature and humidity, reducing material deformation)

Electrostatic protection (ESD) (avoiding electrostatic damage to PCB)

Production line automation (MES system, data traceability)

Summary

To make a PCB drilling machine, you need to comprehensively master mechanical design, CNC control, electrical automation, visual system, PCB process and other knowledge to create high-precision and high-efficiency equipment.

What part of your work are you currently doing? Are you doing whole machine design or focusing on a certain module?

What materials are PCB boards divided into?

PCB (Printed Circuit Board) can be divided into the following main materials according to the substrate type. Each material is suitable for different electronic products and application scenarios:

1. Classification by substrate type

(1) Rigid PCB material

Used in most traditional electronic devices, with stable mechanical strength and electrical performance.

FR-4 (most common)

Composition: glass fiber cloth + epoxy resin + flame retardant

Features: high temperature resistance (TG value is usually 130°C~180°C), good insulation, flame retardant (UL94-V0)

Application: consumer electronics, automotive electronics, industrial control equipment, etc.

CEM-1, CEM-3 (economical alternative to FR-4)

Composition: glass fiber + paper base (CEM-1), or glass fiber + non-woven fabric (CEM-3)

Features: low cost, performance between FR-4 and paper substrate

Application: home appliances, low-end consumer electronics

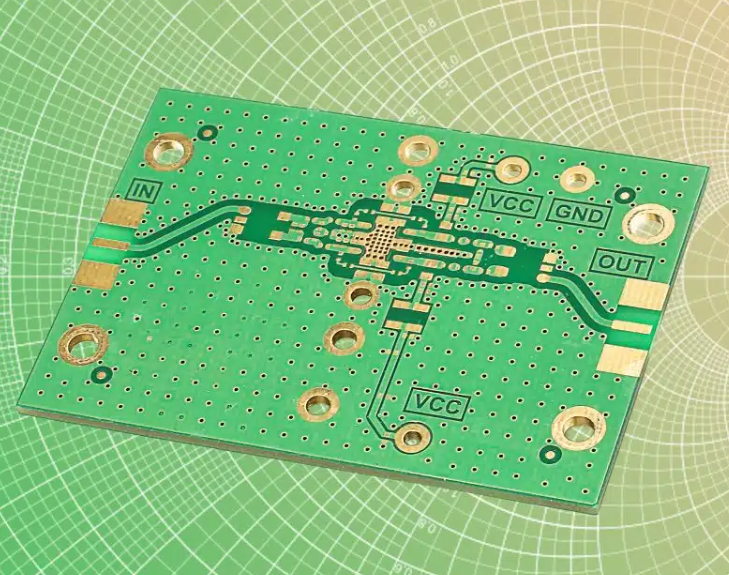

High-frequency materials (PTFE, ceramic filling materials)

Composition: polytetrafluoroethylene (PTFE), ceramic filling materials

Features: low dielectric constant (Dk), low loss (Df), resistance to high-frequency signal interference

Application: 5G communication, satellite communication, RF microwave circuit

Metal-based PCB (aluminum-based, copper-based)

Composition: metal substrate (aluminum, copper) + insulation layer + Copper foil

Features: Excellent thermal conductivity, suitable for applications with high heat dissipation requirements

Applications: LED lighting, power modules, automotive electronics

(2) Flexible PCB materials (FPC)

Used for electronic products that need to be bent or folded.

PI (polyimide, Kapton)

Features: High flexibility, high temperature resistance (resistant to more than 300°C), chemical resistance

Applications: Smart phones, wearable devices, aerospace electronics

PET (polyethylene terephthalate)

Features: Low cost, general temperature resistance (usually less than 150°C)

Applications: Low-end FPC, such as keyboard membrane switches

(3) Rigid-flex PCB materials

Combining FR-4 and FPC materials to achieve a combination of rigidity and flexibility, suitable for complex structures.

Rigid part (FR-4) + flexible part (PI)

Features: foldable and maintains a certain mechanical strength

Applications: high-end consumer electronics, medical equipment, military electronics

2. Classification by heat resistance level (TG value)

**TG (glass transition temperature)** indicates the temperature at which the PCB material changes from hard to soft at high temperature.

TG value Material category Applicable scenarios

Ordinary TG (<130°C) Low-end CEM-1, CEM-3 General home appliances

Medium TG (130~170°C) FR-4 conventional materials Most electronic products

High TG (>170°C) Special FR-4, high-frequency materials Servers, automobiles, 5G equipment

3. Special PCB materials

Ceramic-based PCB (Al₂O₃, AlN)

Features: extremely high thermal conductivity, high temperature resistance

Application: military industry, power semiconductors, laser equipment

HDI PCB (high-density interconnect board)

Material: high TG FR-4, PI

Application: smart phones, chip packaging

Summary

The choice of PCB materials depends on the application scenario:

Ordinary consumer electronics → FR-4

High-frequency communication (5G, RF) → PTFE, ceramic filling materials

High-power heat dissipation (LED, power supply) → aluminum-based, copper-based

Flexible devices (mobile phones, wearables) → PI (polyimide)

High reliability (automobiles, servers) → High TG FR-4

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points