Revolutionizing PCB Processing High Precision Dual Axis Drilling Machine with CCD Vision System

Apr 10, 2025

Revolutionizing PCB Processing: High-Precision Dual-Axis Drilling Machine with CCD Vision System Debuts

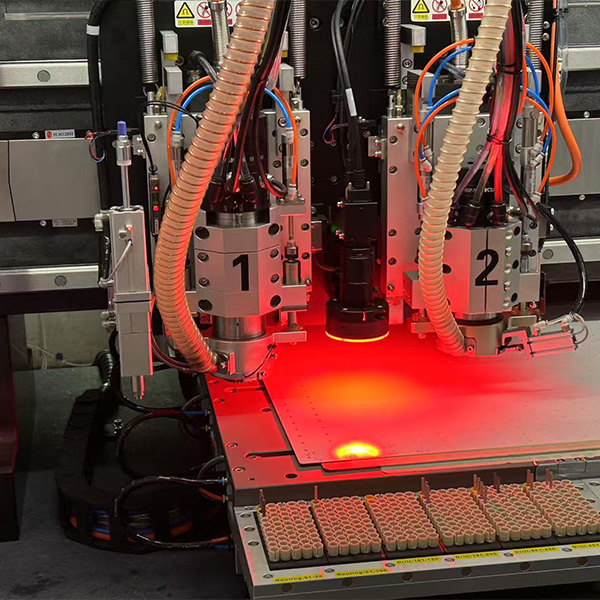

As the electronics manufacturing industry continues to push the boundaries of precision and automation, printed circuit boards (PCBs)—the heart of all modern electronic devices—are also evolving in complexity and production standards. In a major breakthrough, a leading domestic equipment manufacturer has unveiled a dual-axis PCB drilling machine equipped with a CCD vision positioning system, featuring a cutting-edge “one drill, one router” design. With its high-precision engineering and high-performance capabilities, this new machine is already generating excitement throughout the industry.

Dual-Axis Architecture with “One Drill, One Router” for Enhanced Efficiency

One of the most notable innovations in this new system is its independently controlled dual-axis design. Unlike traditional single-head or multi-head drilling machines, this equipment features a high-speed drilling spindle on one axis and a high-RPM routing spindle on the other, allowing simultaneous drilling and slotting operations.

This “one drill, one router” configuration dramatically improves productivity by eliminating the need for tool or equipment changes between drilling and routing stages. It’s particularly advantageous in environments requiring high-mix, low-volume, and quick-turn PCB production, making it a powerful asset for agile manufacturing operations.

CCD Vision System for Micron-Level Positioning Accuracy

The machine is equipped with an integrated high-resolution CCD vision system for intelligent board recognition and auto-alignment. By combining real-time image processing with AI-based correction algorithms, the system can accurately detect fiducial marks, reference holes, and alignment lines—compensating for distortions caused by thermal expansion, warping, or panel shrinkage.

This results in an exceptional positioning accuracy of ±0.004mm, ensuring unparalleled drilling and routing consistency. The machine is ideally suited for advanced applications such as HDI boards, multi-step blind/buried vias, and high-layer-count PCBs that demand ultra-precise processing.

Servo + Linear Motor Dual Drive System for Speed and Stability

The machine features a fully closed-loop servo control system in conjunction with direct-drive linear motors, offering fast, low-vibration, and low-noise operation. The X/Y axes boast a repeatability of ±0.003mm and rapid traverse speeds exceeding 50 meters per minute—striking the perfect balance between speed and motion stability.

In addition, the platform is equipped with an advanced damping system and thermal compensation control, allowing long-duration continuous operation without performance degradation—a vital feature for 24/7 production environments.

Versatile Board Compatibility and Custom Production Support

The machine supports a wide range of PCB sizes, from 50x50mm up to 650x600mm, and is compatible with single-sided, double-sided, multilayer, and flexible (FPC) boards. Thanks to its modular clamping and vacuum systems, users can easily switch between different board formats to accommodate diverse production needs.

On the software side, the system provides automated Gerber file import, real-time path optimization, and batch job management, creating a seamless bridge from digital data to physical product in a fully smart production workflow.

Eco-Friendly, User-Focused Design with Advanced Safety Features

Beyond its impressive performance, the machine incorporates thoughtful design elements focused on environmental protection and operator safety. A high-efficiency dust collection and chip removal system ensures clean processing with minimal environmental impact. The machine also includes multi-layer safety mechanisms, such as automatic error alerts, emergency stop functions, and user-level access controls to safeguard both the machine and its operators.

Setting a New Standard in Intelligent PCB Manufacturing

Industry experts see this new drilling machine as a milestone in the evolution of PCB processing technology. It not only reflects the growing demand for drilling-routing integration, but also showcases the technological maturity of domestic manufacturing in precision motion control, machine vision, and automation software.

As PCBs become denser and more complex, especially in high-end sectors like 5G, automotive electronics, aerospace, and medical devices, manufacturers are under increasing pressure to deliver flawless quality with faster turnaround times. This dual-axis drilling solution directly addresses these challenges, offering a smart, scalable, and precision-focused platform for next-generation PCB production.

According to early adopters, the machine has already passed validation at several major PCB production facilities, with excellent performance in both pilot and mass production scenarios. With its broad applicability and reliable performance, it is expected to play a key role in upgrading production lines across various high-tech industries.

About the Manufacturer

The equipment is developed by a prominent Chinese electronic machinery company with a strong track record in precision electronics manufacturing solutions. With dozens of patents and proprietary technologies under its belt, the company specializes in developing high-end PCB processing, semiconductor packaging, and optoelectronics equipment.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points