Key Aspects of Quality Inspection Standards for PCB Circuit Boards

Jun 24, 2023

Key Aspects of Quality Inspection Standards for PCB Circuit Boards

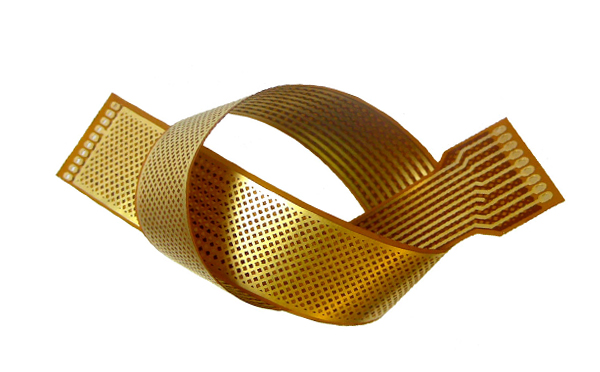

After PCB manufacturing, it is necessary to perform inspections to determine whether the quality is compatible with the design requirements.

The quality inspection of PCB circuit boards generally includes visual inspection, connectivity inspection, and solderability inspection.

1. Visual Inspection Standards for PCB Circuit Boards:

(1) Check if the surface of the PCB circuit board is smooth, flat, and free from bumps or scratches. Look for drilled holes with missing or misplaced drills or instances where the surrounding copper foil is pierced.

(2) Assess the integrity of wire patterns by overlaying a photographic film on the PCB circuit board to measure the width and shape of the wires. Check for solder mask voids or breaks, jagged gaps along the edges of the traces, and unintended wire short circuits.

(3) Verify if the dimensions of the PCB circuit board's outer edges meet the requirements.

2. Connectivity Inspection Standards for PCB Circuit Boards:

Connectivity inspection is required for multi-layer PCB circuit boards. Typically, a multimeter is used to test the connectivity of the PCB circuit board's circuits.

3. Solderability Inspection Standards for PCB Circuit Boards:

This inspection evaluates the solder's ability to wet the PCB circuit board's patterns when soldering components onto it.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points