Causes and Solutions for PCB Process Defects: Substrate Edition

Jul 29, 2024

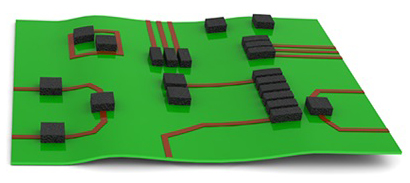

Causes and Solutions for PCB Process Defects: Substrate Edition

•

In today's rapidly advancing technological era, various high-tech electronic products are emerging continuously, leading to a sharp increase in the demand for printed circuit boards (PCBs). The manufacturing difficulty is getting higher, and the quality requirements are becoming more stringent.

•

To ensure high quality and stability of printed circuit boards and achieve comprehensive quality management and environmental control in PCB factories, it is necessary to fully understand the characteristics of PCB manufacturing technology.

•

PCB manufacturing technology is a comprehensive technological crystallization, involving basic knowledge in many fields such as physics, chemistry, optics, photochemistry, polymers, fluid mechanics, and chemical kinetics. These include the structure, composition, and performance of materials; the precision, stability, efficiency, and processing quality of process equipment; the feasibility of process methods; the precision and high reliability of detection means; and issues such as temperature, humidity, and cleanliness in the environment. These issues directly and indirectly affect the quality of PCBs.

•

Since many aspects and issues are involved, various quality defects can easily occur. Therefore, it is necessary to thoroughly understand the most common quality problems in each process step, quickly take process measures to eliminate them, and improve PCB production efficiency. We have collected, summarized, and organized materials on this topic for the readers. Here, we will first discuss the problems related to PCB substrates:

•

•

1. Changes in Substrate Dimensions During PCB Manufacturing

(1) Differences in Warp and Weft Direction Causing Changes in Substrate Dimensions:

Due to the neglect of fiber direction during shearing, residual shearing stress remains in the substrate. Once released, it directly affects the shrinkage of the substrate dimensions.

Solution: Determine the pattern of changes in warp and weft directions and compensate on the film according to the shrinkage rate (this should be done before photoplotting). Also, shear according to the fiber direction or process according to the character marks provided by the PCB manufacturer on the substrate (generally, the vertical direction of the characters is the longitudinal direction of the substrate).

(2) Changes in Substrate Dimensions When Copper Foil on the Surface is Etched Away:

When stress is relieved, dimensional changes occur.

Solution: Design the circuit to distribute as evenly as possible across the entire board. If this is not possible, ensure there are transition sections in the space (not affecting the circuit position). This is because the density differences in the warp and weft yarns in the glass cloth structure of the board material lead to differences in warp and weft strength.

(3) Deformation of the Substrate Due to Excessive Pressure During Brushing:

Solution: Perform test brushing to keep process parameters in optimal state, then brush the board. For thin substrates, use chemical cleaning or electrolytic cleaning methods.

(4) Incomplete Curing of Resin in the Substrate Leading to Dimensional Changes:

Solution: Use baking methods to resolve this. Especially before drilling, bake at 120°C for 4 hours to ensure resin curing and reduce the impact of thermal cycling, preventing dimensional deformation of the substrate.

(5) Poor Storage Conditions for Thin Substrates or Prepreg Before Laminating Multilayer Boards:

Solution: Bake the treated substrates to remove moisture and store the treated substrates in a vacuum drying oven to prevent re-absorption of moisture.

(6) Excessive Resin Flow During Lamination of Multilayer Boards Causing Glass Cloth Deformation:

Solution: Perform process test pressing, adjust process parameters, then press. Also, select the appropriate resin flow amount based on the characteristics of the prepreg.

2. Bending (BOW) and Twisting (TWIST) of Substrates or Laminated Multilayer Substrates

(1) Long-Term Stress Accumulation Due to Vertical Placement of Thin Substrates:

Solution: Horizontally place thin substrates to ensure uniform stress in all directions, minimizing dimensional changes. Store in original packaging on flat shelves, avoiding high stacking and heavy pressure.

(2) Rapid Cooling or Improper Cooling Process After Hot Air Leveling or Hot Melt:

Solution: Place on a special cooling plate to naturally cool to room temperature.

(3) Long Periods of Alternating Hot and Cold During Processing, Combined with Uneven Internal Stress Distribution:

Solution: Adjust hot and cold exchange rates during processing to avoid abrupt temperature changes.

(4) Incomplete Curing of the Substrate Causing Concentrated Internal Stress:

Solution:

A: Re-cure according to the hot pressing process.

B: To reduce residual stress in the substrate, improve dimensional stability, and prevent warping, use pre-baking at 120-140°C for 2-4 hours (depending on board thickness, size, quantity, etc.).

(5) Differences in Copper Foil Thickness on the Top and Bottom Surfaces of the Substrate:

Solution: According to lamination principles, compensate for the differences caused by varying copper foil thicknesses with different thicknesses of prepreg.

3. Surface Pits or Voids and Foreign Inclusions in Multilayer Substrates

(1) Copper Nodules or Resin Protrusions and Foreign Particles Embedded in Copper Foil:

Solution: Replace raw materials by contacting suppliers.

(2) Transparent Appearance on the Substrate Surface After Etching, Voids Visible Upon Sectioning:

Solution: Address as described above.

(3) Black Spots Appearing on Thin Substrates After Etching:

Solution: Address as described above.

4. Common Defects on Copper Surfaces of Substrates

(1) Dents or Pits on Copper Foil Due to Foreign Substances on the Surface of Tools Used During Lamination:

Solution: Improve lamination and pressing environment to meet cleanliness requirements.

(2) Dents and Glue Spots on Copper Foil Due to Foreign Substances on Pressing Molds and Laminating Tools:

Solution: Thoroughly inspect mold surfaces and improve working environment in laminating and pressing areas to meet process requirements.

(3) Poor Surface Condition of Copper Foil Due to Improper Tools During Manufacturing:

Solution: Improve operating methods and select appropriate process methods.

(4) Wrinkles on Copper Foil of Laminated Multilayer Boards Due to Sliding and Improper Resin Flow During Lamination:

Solution: Ensure accurate positioning of layers during lamination and carefully handle stainless steel plates directly contacting copper foil, keeping them flat.

(5) Glue Spots on Substrate Surface Due to Glue Chips Falling on Steel Plates or Copper Surfaces During Lamination:

Solution: To prevent glue chips from falling off, thermally seal the edges of the prepreg.

(6) Pinholes on Copper Foil Causing Resin to Overflow During Pressing:

Solution: Inspect incoming copper foil under backlight and store qualified materials properly to avoid creases or tears.

5. White Spots or White Stains Inside the Board

(1) Local Separation of Resin and Glass Fibers Due to Inappropriate Mechanical Force:

Solution: Reduce or mitigate excessive vibrations during mechanical processing to lessen the impact of mechanical force.

(2) Regular White Spots Formed by Fluorine-Containing Chemicals Seeping into the Board and Corroding Glass Fiber Weave Points:

Solution: This often occurs during tin-lead alloy stripping, especially between gold-plated connector fingers. Select suitable tin-lead stripping solutions and processes.

(3) White Spots or Stains Caused by Improper Thermal Stress:

Solution: Avoid defects caused by thermal stress during hot air leveling, infrared hot melting, etc., by ensuring proper temperature control.

By addressing these issues, you can improve the quality of your PCBs and enhance the overall efficiency of your production processes.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

May 12, 2025

China PCB Drilling Routing machine Development

May 06, 2025

PCB Design Process and Key Points