.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Mini 5-axis Engraving and Milling Machine

| NO. | ITEM | CK-150-ATC-5 | |

| A | Machine parameters: | ||

| 1 | The machine body and all parts are made of nano castings. | ||

| 2 | Table size | Ǿ100mm | |

| 3 | Maximum load | 20KG | |

| 4 | Maximum feed height | 200mm | |

| 5 | Spindle to table distance | 30-200mm | |

| 6 | Three-axis travel X/Y/Z | 300/150/170mm | |

| 7 | Spindle outer diameter | Ǿ62 | |

| 8 | Spindle speed | 0-60000RPM | |

| 9 | Spindle motor power | 2.5KW (optional Ǿ80, 4KW 40000 rpm ISO20 spindle) | |

| 10 | Tool magazine | 12 pcs (ISO20 only 10pcs) | |

| 11 | Tool change time | ≤6s | |

| 12 | Spindle taper | Standard T11 (ISO optional) | |

| 13 | Tool magzine category | Disc servo tool magazine | |

| 14 | Rapid speed of X/Y/Z Axis | 12/12/12m/Min | |

| 15 | Processing Speed | 6-12m/Min | |

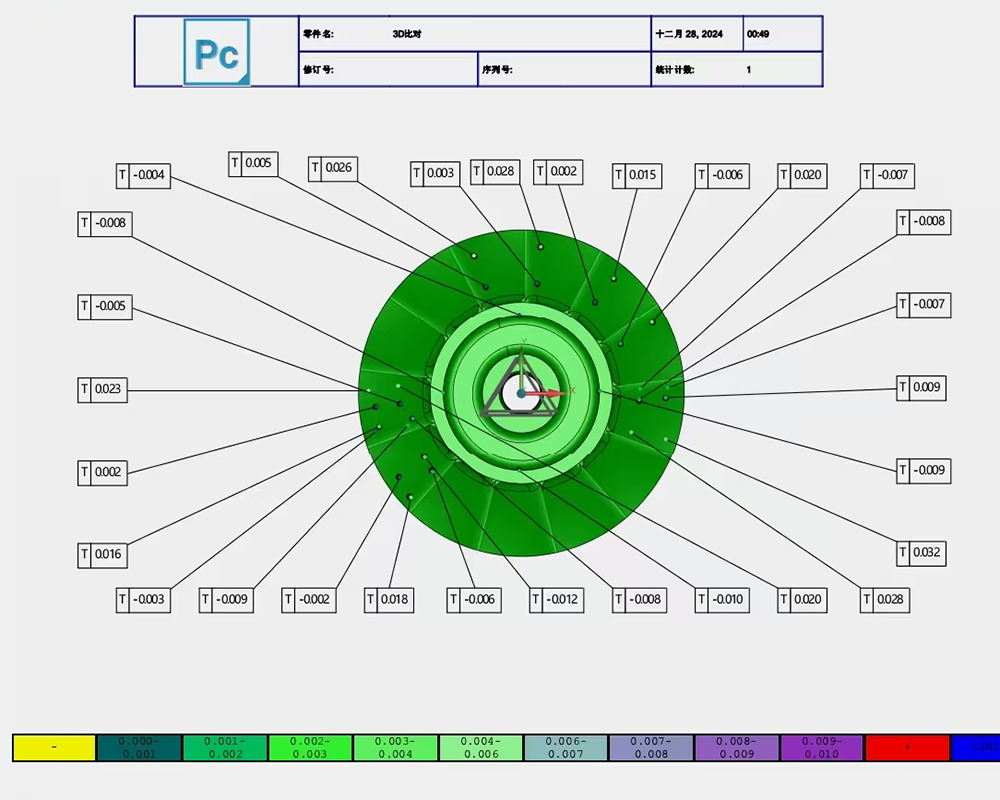

| 16 | Positioning Accuracy | ±0.006/300mm | |

| 17 | Repeatability | ±0.006/300mm | |

| 18 | Machined surface accuracy | ≤Ra3.2-1.6 | |

| 19 | Processing accurancy | ±0.02-0.03mm (calibrated by Renishaw ballbar, UK) | |

| 20 | Working voltage | 220V±10%/110V±10% | |

| 21 | Machine size (L * W * H) | 870×910×1900mm | |

| 22 | Machine weight | 650KG | |

| B | 5- Axis parameters: | ||

| 1 | Fourth axis B axis rotation angle | ±105 degrees | |

| 2 | Fifth axis C axis rotation angle | 360 degrees | |

| 2-1 | Repeatability of B-axis and C-axis | ±15 degree/s | |

| 2-2 | Positioning Accurancy of B-axis and C-axis | ±30-60 degree/s | |

| 3 | Turntable response time | ≤0.1s | |

| 4 | 5-Axis Linkage Mode | 3+2 or 4+1 and five-axis simultaneous motion function (with RCTP optional) | |

1. The machine body and various parts are made of nano castings.

2. This machine is mainly used for precision processing of ivory carving, gold and silver jewelry, precious metals and other metals.

- Equipped with gold and precious metal recovery capabilities, achieving a gold recovery rate of 999‰.

- Capable of turning, engraving, milling, cutting, planing, and drilling.

- Possesses strong high-speed precision machining capabilities.

- Can perform five-axis linkage functions using G-code.

- Equipped with ATC (Automatic Tool Changer) function

- Professional processing of gold bracelets and rings for jewelry.

- Professional manufacturing of dental and other medical devices.

- Precision parts manufacturing for high-end watches.

- High-gloss product finishing.

- Manufacturing of complex small metal parts.

.jpg?x-oss-process=image/resize)